How to record and reduce machine downtimes in 3 steps

Recording and reducing machine downtimes, thereby saving costs and increasing OEE (Overall Equipment Effectiveness) or overall plant effectiveness. This is what almost all manufacturing companies are working towards. Industrial Smartwatches with the right software are particularly suitable for this purpose due to their characteristics.

Often machine downtimes are not detected and recorded at an early stage because machine-human communication in many companies still functions as it did 20 years ago: With signal lights and static screens. Even if a control system such as an MES (Manufacturing Execution System) is in place, it often takes a long time to find the right contact person to rectify the machine malfunction and take care of the problem. Unfortunately, in most cases there is also no precise information about the reason for the fault, but only a rough categorization such as “mechanical fault” or “electrical fault”.

It is therefore more important than ever that the right information reaches the right person at the right time. Therefore we describe in 3 steps how to shorten reaction times by means of Smartwatches and how to optimize machine operation and maintenance processes.

Step 1:

Display machine data on an industry Smartwatch

If wearables such as Industry Smartwatches are used to optimize machine operation and maintenance processes, the question often arises as to how malfunctions of the various machines can be displayed to employees on an Industry Smartwatch.

Depending on how far the company has progressed in digitization, different options can be considered.

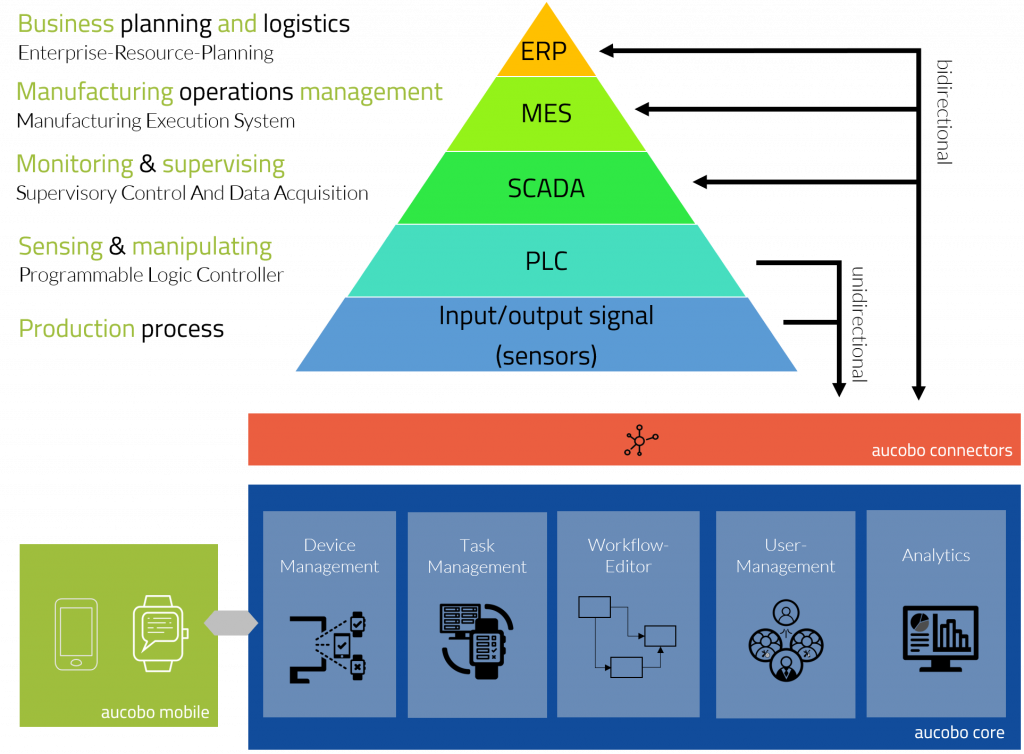

– Connection of the aucobo system to a leading layer

Via the aucobo connector a connection to an ERP, SCADA or MES system can be realized. The big advantage is that data can be exchanged bidirectionally. Machine malfunctions, limit values, orders, etc. that are present in the control system can be displayed on the Smartwatch. In return, data generated by the Smartwatch can be fed back into the control system. Relevant data is defined in advance for this purpose.

– Connection of the aucobo system to the programmable logic controller (PLC)

It is also possible to connect the PLC of a machine via the aucobo connector to obtain machine data. The PLC should not be too old for this (e.g. Simatic S7). The connection process must be carried out individually for each PLC. This is very time-consuming and cost-intensive. In addition, the question of warranty on the part of the manufacturer arises if changes are made to the PLC. With this type of connection only a one-sided data exchange is possible.

– Obtaining machine data via sensors

If no control system is available or not all machines are connected to it, it is possible to transmit important error messages directly to the aucobo system via sensors. This is done with our simple aucobo sensor system. It is not possible to transmit the exact reason for the malfunction to the employee. He only receives a general error message.

Step 2:

Improve data quality

The Industrie Smartwatch offers the possibility to significantly improve the data situation in case of machine malfunctions. Hidden potential for optimization can thus be uncovered.

On the one hand, the employee can document problems that have led to a machine malfunction directly on the wrist with little effort. In this way, even micro-faults can be recorded simply and effectively. This saves the employee time and relieves him of the tiresome and often neglected task of documenting all the faults of the day at the end of the shift. The Smartwatch also improves data quality by determining the exact nature of the disorder.

Furthermore, the aucobo system automatically records how long it took until a task was accepted, whether the problem could be solved or whether further help was needed and how long it took overall.

Step 3:

Optimize processes

By combining the collected data, the average availability of the plant can be determined much more precisely. Machine downtimes due to malfunctions are no longer unexpected events, but become a calculable factor.

Troubleshooting processes can be constantly monitored, continuously optimized and the effectiveness of optimization measures can be easily and quickly checked.