Smart wearables are already widely used in today’s industry. The Hype Cycle is suitable as a visual tool to illustrate the maturity and acceptance of

Future Factory Blog

Get ready for the next industrial revolution. Tips and information about machine operation, maintenance, logistics & shop floor management – be smart, watch your productivity!

Maximizing Efficiency: A Guide to Operational Excellence

Posted on 16. December 2024

Operational excellence has become a buzzword in the manufacturing industry. But what exactly is operational excellence? In simple terms, it is the pro

Lean Digital – The New Way of Using Lean Management in Production

Posted on 20. October 2024

In today’s rapidly evolving manufacturing landscape, companies are constantly seeking ways to improve their operations and stay ahead of the competiti

Predictive maintenance with the help of smart wearables

Posted on 21. May 2024

In manufacturing, coordinated process chains that go hand in hand are a prerequisite for keeping up with the competition. Predictive maintenance refer

Blind spot shop floor communication: how aucobo enhances the digital twin

Posted on 15. April 2024

Digitization is advancing in the industry with great strides. Automated machines, digital twins of production plants, and digital storage spaces for d

Relieving the employees and reducing stress with the help of the aucobo solution

Posted on 25. January 2022

In today’s corporate world, there is constantly the question of satisfying the customer and how they receive the required performance from companies.

How is the industrial world of work changing with the implementation of smart wearables?

Posted on 11. January 2022

In the sector of industrial production, the usage of smart wearables is becoming more and more important especially for employees. While economic aspe

The aucobo solution for optimized material supply

Posted on 21. December 2021

The areas of logistics and assembly in manufacturing companies are often only weakly automated and little digitized. This is particularly true for sma

Sustainability in production: How smart technologies help to make the shop floor greener

Posted on 7. December 2021

The topic of sustainability is no longer a foreign word in the corporate world. When it comes to positioning themselves successfully on the market in

Successfully implementing agile manufacturing with the help of smart wearables

Posted on 23. November 2021

The implementation of agile manufacturing with the help of smart wearables brings many advantages for manufacturing companies. At the same time, rigid

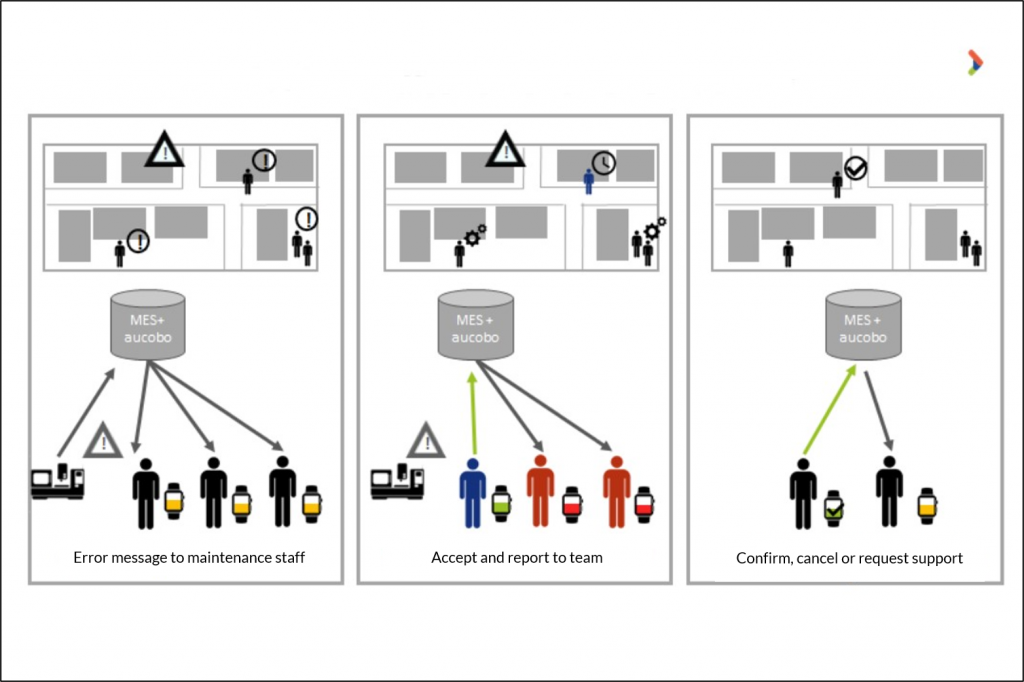

Aucobo solution reduces reaction times

Posted on 9. November 2021

Reducing reaction times in the production is an important issue in the industry. This also applies to the area of fault messages in maintenance. The a

On premise vs. cloud software – which solution optimizes manufacturing?

Posted on 28. October 2021

In today’s world of enterprise IT, the question is how companies want to build their software infrastructure. There are two different options for this

The use of smart wearables to increase productivity on the shop floor

Posted on 14. October 2021

Manufacturing companies face the daily challenge of increasing their productivity and flexibility in production. One important aspect of this is to im

Increase machine capacity with industrial smartwatches

Posted on 16. September 2021

Increasing machine capacity in production is one of the supreme disciplines of process optimization. The reason for this is the complexity of the task

The different types of smart wearables in the industry

Posted on 21. July 2021

Smart wearables are intelligent miniature systems that are embedded in everyday objects or can be worn on the body. They are part of the Internet of T

Aucobo solution reduces machine downtime

Posted on 23. June 2021

There are numerous possible applications for the aucobo solution in production and logistics. This also applies to the area of machine downtime. The a

8 steps for successful digitization in companies

Posted on 11. June 2021

In this article, we have summarized the 8 steps for successful digitization in companies from our project experiences. Many companies are still strugg

Why the digitization in production pays off

Posted on 20. May 2021

A large number of companies in Germany are already focusing on digitization in production. Some have put it on their agenda, increasingly since the pa

Aucobo solution optimizes quality checks

Posted on 14. May 2021

There are numerous possible applications for the aucobo solution in production and logistics. This also applies to the area of quality checks. The auc

Optimization of processes in production with the help of industrial smartwatches – Part 2: Hardware

Posted on 29. April 2021

In order to the industrial smartwatch to be used to optimize processes in production, the interaction between software and hardware must function flaw

Optimization of processes in production with the help of industrial smartwatches – Part 1: Software

Posted on 22. April 2021

The digitization of production facilities in Germany continues to make progress and has been increasingly implemented, especially since the pandemic.

Smart Maintenance – the key to increasing machine productivity

Posted on 20. April 2021

Maintenance is often a very complex process, especially in big companies. There are different ways to do maintenance whereas the following are most co

With employee-friendly data to more employee satisfaction in the industry

Posted on 25. March 2021

Around 67% of companies are not satisfied with the results of data analysis in the production area. False alarms result in high costs, the production

Micro-disruptions – How short machine downtimes slow down the productivity of people and machines

Posted on 9. March 2021

Interruptions and machine malfunctions are not uncommon on the shopfloor. Many can be pinpointed and the cause of the problem quickly identified and r

Why successful companies invest in empowering employees on the shopfloor

Posted on 15. February 2021

In order to create a successful and future-oriented company, qualified and motivated employees are required. The world of work is constantly changing

Increasing efficiency on the shopfloor with internal communication

Posted on 9. February 2021

Finding good, motivated and committed employees is becoming an increasingly difficult task that the management of a company must master. It is therefo

6 things that can increase employee satisfaction on the shopfloor

Posted on 2. February 2021

Demotivation among employees is expensive. Around 30% of the average loss in productivity and work performance is due to a lack of employee motivation

How smart wearables support the continuous improvement process on the shopfloor

Posted on 18. January 2021

In order to be competitive on the market in the long term, it is essential to continuously adapt and improve or optimize existing processes. In many c

4 factors for an innovative manufacturing environment

Posted on 18. January 2021

More and more companies are focusing on Industry 4.0 or Production 4.0 and the production environment is constantly changing. This brings new opportun

How to use the Pareto principle in lean manufacturing

Posted on 8. January 2021

Different problems occur over and over again on the shopfloor – but which ones should be fixed first or where does it make sense to start? The correct

How aucobo supports Santa Claus at the North Pole

Posted on 17. December 2020

Every year around Christmas Santa Claus is doing an enormous amount of work so that everyone gets their presents on time. When you consider how many p

The new concept of communication on the shopfloor

Posted on 27. November 2020

Not only intact machines are essential for optimal production – good communication between the individual store floor employees also plays a major rol

Lean Manufacturing

Posted on 23. November 2020

Lean Production or also called Lean Manufacturing is a term that is originated in the 1950s at Toyota in Japan. The idea of Lean Manufacturing is to r

Shopfloor optimization with Smart Wearables

Posted on 16. November 2020

Reducing waste and costs is one of the core issues in the Lean Production. But this alone does not necessarily lead to an improved production process

Types of waste

Posted on 10. November 2020

Classic lean production should lead to increased productivity and simultaneously lower costs. Continuous improvements lead to better control, optimiza

The implementation of a safe working environment

Posted on 30. October 2020

The working environments and workplaces in today’s industry are constantly changing. Risk assessments that were valid yesterday are already outdated t

How to simplify shift handovers using smart wearables

Posted on 14. October 2020

Many industrial companies produce their goods in shifts. Production often takes place around the clock – divided into early shift, late shift and nigh

Industry Smartwatch vs. Consumer Smartwatch

Posted on 7. October 2020

Smartwatches are increasingly becoming our everyday companion – in the private as well as in the industrial sector. But what are the differences betwe

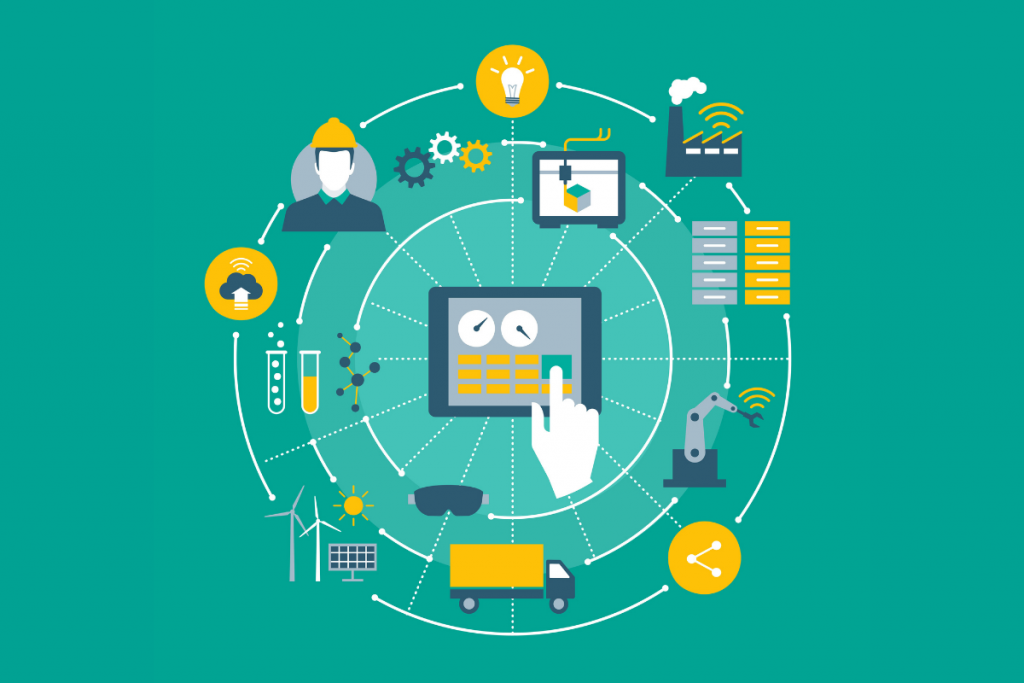

How wearables can help in industrial environments

Posted on 11. September 2020

Since WiFi 6 and with 5G it is evident: The future is connected. But what are wearables and what do they have to do with a connected future? Wearables

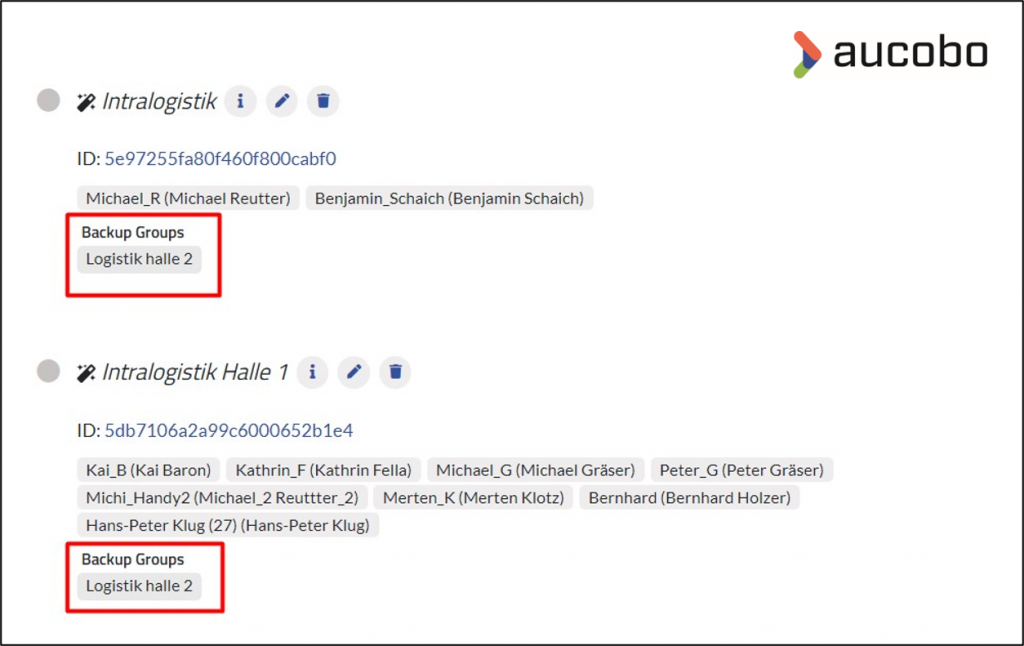

New feature – Backup groups

Posted on 8. July 2020

Description With the last update we have included backup groups in our software. This feature allows to add backup groups to user groups in the aucobo

What are escalations on the shop floor?

Posted on 7. July 2020

If a production employee is assigned a task and, for whatever reason, it is not processed, this not only leads to inefficient processes but also cause

New Feature – Photo interaction

Posted on 24. June 2020

Description With the last update we have included the photo feature in our software. This feature makes it possible to take photos directly via a phot

Optimizing multiple machine operation with Industrial Smartwatches

Posted on 17. June 2020

Today, production employees are usually informed of a machine malfunction by means of acoustic signals, flashing signal lights or monitors. As a resul

Optimize OEE – How to increase the overall equipment effectiveness

Posted on 5. June 2020

Every manufacturing company is interested in increasing its Overall Equipment Effectiveness (OEE). The OEE of a plant is defined as the product of the

How to record and reduce machine downtimes in 3 steps

Posted on 27. May 2020

Recording and reducing machine downtimes, thereby saving costs and increasing OEE (Overall Equipment Effectiveness) or overall plant effectiveness. Th

3 tips for avoiding contact on the shop floor

Posted on 6. May 2020

Manufacturing companies face the challenge of maintaining production despite the current corona crisis. In order to avoid a production stop, employee

Tools for better communication in the home office

Posted on 12. April 2020

Due to the current situation around COVID-19 many employees are currently in the home office and communicate exclusively remotely with colleagues, tea

Coronavirus and the effects on production [+ Checklist]

Posted on 31. March 2020

It feels like Germany is currently working completely from the home office because of COVID-19. Even in areas where a home office is not possible, eve

4 things to keep in mind when operating multiple machines

Posted on 3. March 2020

Due to the constantly increasing degree of automation, the relationship between people and machines in production has changed. While a few years ago i

4 steps to achieve an optimal maintenance management

Posted on 25. October 2019

How you can use maintenance management productively to solve common problems and thus make your production more efficient. Industrial production has b