Smart Wearables in the Industry – Current Status and Hype Cycle

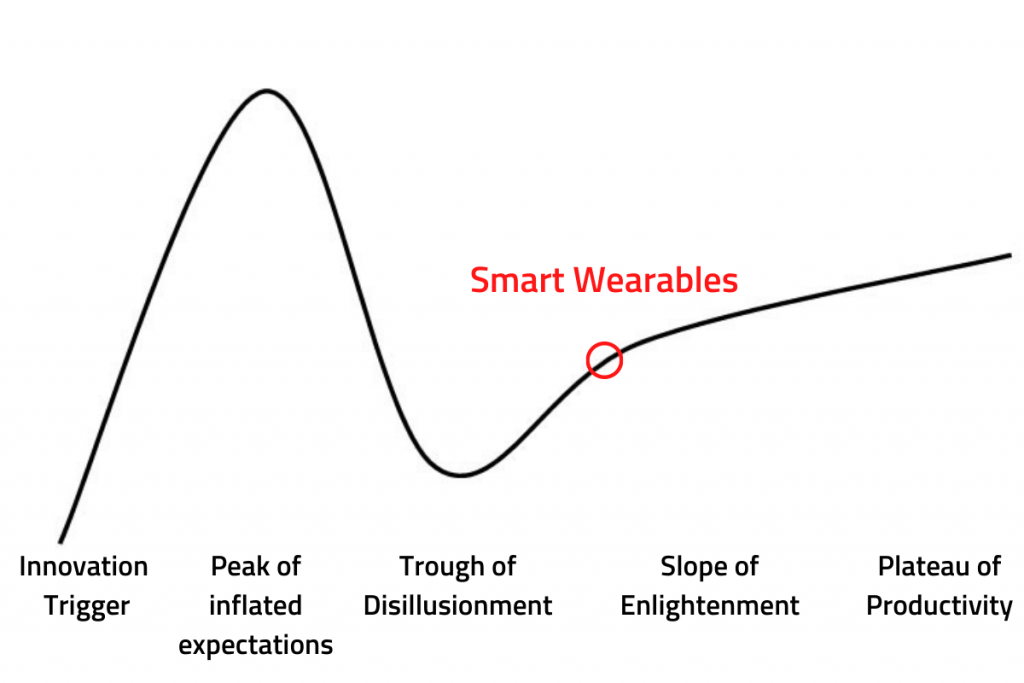

Smart wearables are already widely used in today’s industry. The Hype Cycle is suitable as a visual tool to illustrate the maturity and acceptance of new technologies. It also shows the current development status and future expectations of the respective technology.

Phases of the Hype Cycle

The hype cycle is a graphical representation of the life cycle stages a technology goes through from conception to maturity and widespread adoption. It begins with the innovation trigger. This phase describes the first breakthrough or new introduction of a new technology.

After initial press and media resonance, an enormous amount of interest and speculation is generated. This upswing is described as a hype phase followed by a peak of inflated expectations.

When the initial media vortex around the new technology is over and it fails to meet expectations quickly enough, consumer interest drops. The declining interest leads to disillusionment and ends with a low point.

Although no longer in the media headlines, companies still work on the technology to understand how it can be improved. This is where methods and best practices start developing.

By educating and filtering out specific use cases, the cycle curve can slowly rise again.

The final phase is the productivity plateau. A slowly creeping stagnation of the curve indicates that the technology has become stable. The strong growth in acceptance leads to a growing adoption of the technology by the potential target group.

Current status of smart wearables in the industry

Smart wearables are already finding a wide variety of applications in the industry. They are currently in the upswing phase, where an increase is taking place thanks to the filtering out of concrete use cases.

Smart wearables have long since ceased to be a “trendy gadget” in the industry. The current status shows that there are now real use cases that offer a high degree of added value.

Industrial sectors such as production, logistics and maintenance are areas of application that are increasingly using the new technologies.

A wide variety of smart wearables, such as smartphones, tablets and smartwatches, but also smart glasses and smart gloves, are implemented here.

Use cases smart wearables

For production, smartwatches in particular offer great added value for any processes on the shop floor. This form of intelligent hardware, in conjunction with suitable software, can significantly facilitate the digitization of production processes.

Smart wearables in production

By using intelligent collaboration solutions, employees can be digitally connected with each other on the shop floor. What does that mean in concrete terms? Workers on the production floor are equipped with smartwatches. These will be integrated in combination with a digital collaboration platform. This now makes it possible to communicate the relevant information to the right worker at the right time. The workers are also able to communicate more efficiently with each other.

This allows information and work orders to be transmitted and forwarded in real time. Likewise, workers can quickly contact their colleagues if they need assistance with an order execution.

In addition to connecting employees, smart wearables can also be used to connect man and machine on the shop floor. What does that mean in concrete terms? The machine data is tapped directly at the plant or integrated from overarching MES systems. This means that all relevant messages and data can now be sent to the smartwatch of the responsible worker without delay.

For example, if a machine malfunction occurs, the message is immediately transmitted digitally to an available worker. The worker can then see on the smartwatch which machine is involved and what type of fault message is present. The transmission of the fault messages in real time enables a fast response and can reduce downtimes enormously.

Smart wearables in logistics

In logistics, smartwatches and smart gloves are often integrated to digitize scanning processes. With the help of integrated scanners on the respective smart wearable, logisticians can quickly and digitally scan material stocks or initiate transport orders.

Smart wearables in maintenance

The use of smartwatches in maintenance enables digital documentation of all quality-assuring work processes and data. Work orders can be carried out and documented by integrated step-by-step instructions with a click on the smartwatch.

Another advantage of using smartwatches is the communication between the individual areas. For example, if the material has been processed in production, the logistics area can react immediately and provide new material. Likewise, maintenance staff are notified immediately if a machine on the shop floor comes to a standstill.

In addition to saving time, the use of smart wearables in the industry has a high potential for cost savings. Digital networking of machines and workers can reduce downtimes, increase machine availability and reduce buffer stocks.

In addition, the use of smart wearables leads to enormous stress reduction for employees. They are relieved by the simple and fast communication and have more time to perform their tasks. An overstimulation in production is counteracted and the employees receive only the information that is relevant for them in a targeted and reliable manner.

The aucobo collaboration platform for the industry

Aucobo’s intelligent collaboration platform offers an efficient solution to digitalize communication and collaboration on the shop floor. By integrating the aucobo solution, man and machine can be connected in the production.

Thanks to the hardware-independent solution, the aucobo collaboration platform can be used for a wide variety of areas and can be integrated with a wide variety of smart wearables. Individual workflows can be created within minutes and executed digitally on site.

The aucobo solution is already widely used in production, logistics and maintenance and has been successfully implemented for various use cases. It enables a reduction of response times by 80%, of downtimes by 30% as well as a 30% increase in OEE.

In this way, aucobo is able to revolutionize the entire shop floor, relieve employees and increase the overall efficiency of numerous companies..

You want to digitize your shop floor and thereby increase your efficiency? Feel free to make an appointment for an initial exchange!

Connect your workers and machines with the help of the intelligent aucobo collaboration platform!

Contact us now and receive comprehensive advice.